![]() How often should you sealcoat?

How often should you sealcoat?

![]() Your parking lot should be sealcoated at least every 2 to 4 years. A newly laid asphalt parking lot should be sealed after 6 months of curing. Because of the ever-increasing costs of asphalt, many business owners now seal every other year. This has proven to be an excellent approach to avoid expensive repairs and maintain an aesthetically pleasing parking lot. There are many factors to consider when deciding how often to sealcoat. How much traffic does the pavement receive, what are the weather conditions like, and what applications methods were used when applying the sealer are all things that would affect its longevity.

Your parking lot should be sealcoated at least every 2 to 4 years. A newly laid asphalt parking lot should be sealed after 6 months of curing. Because of the ever-increasing costs of asphalt, many business owners now seal every other year. This has proven to be an excellent approach to avoid expensive repairs and maintain an aesthetically pleasing parking lot. There are many factors to consider when deciding how often to sealcoat. How much traffic does the pavement receive, what are the weather conditions like, and what applications methods were used when applying the sealer are all things that would affect its longevity.

![]() Have you noticed that new asphalt is jet black but soon begins to fade and in a year or two has turned gray and develops cracks? That’s oxidation. The effects of the sun and rain/snow oxidizing the asphalt. Given enough time the pavement becomes brittle and has less resistance to the loads placed on it. This can lead to a multitude of problems.

Have you noticed that new asphalt is jet black but soon begins to fade and in a year or two has turned gray and develops cracks? That’s oxidation. The effects of the sun and rain/snow oxidizing the asphalt. Given enough time the pavement becomes brittle and has less resistance to the loads placed on it. This can lead to a multitude of problems.

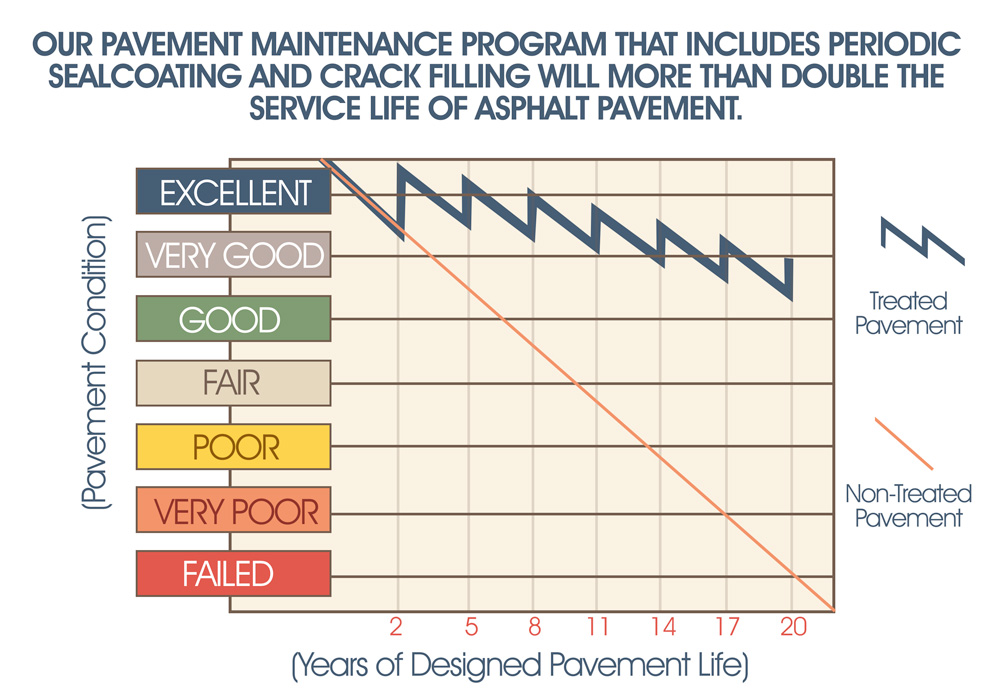

Some common factors include motor oil,other vehicle fluids, gasoline, lawn care chemicals, soaps and solvents. A good quality sealcoating will protect the asphalt pavement from all these damaging factors while providing the curb appeal of a new-looking black appearance, while adding years to the life of the pavement. It’s often overlooked that sealcoating not only seals the harmful elements out but seals the beneficial properties of the asphalt in. Many years of research has proven that proper maintenance including sealcoating can double the life of an asphalt pavement.

![]() What about those cracks in my driveway?

What about those cracks in my driveway?

![]() Those need immediate attention. A host of problems leading to major failure can result from the small start of a few cracks left unattended. Actual cracks in the pavement require specialized crack sealant materials. Left alone cracks allow moisture to penetrate the asphalt surface. Water expands as it freezes, so moisture in the cracks does the greatest damage in the winter months. The main issue in sealing cracks is that they MUST be clean, dry, and have no vegetation present prior to any sealing. Our crack filler allows the sealant to expand and contract with the pavement.

Those need immediate attention. A host of problems leading to major failure can result from the small start of a few cracks left unattended. Actual cracks in the pavement require specialized crack sealant materials. Left alone cracks allow moisture to penetrate the asphalt surface. Water expands as it freezes, so moisture in the cracks does the greatest damage in the winter months. The main issue in sealing cracks is that they MUST be clean, dry, and have no vegetation present prior to any sealing. Our crack filler allows the sealant to expand and contract with the pavement.

![]() How to avoid Crack Discoloration?

How to avoid Crack Discoloration?

![]() Crack discoloration is a common issue that arises when water comes up through the pavement where cracks or pavement failure is occurring. As the days get warmer, the sun heats up the pavement and draws the moisture back to the surface.

Crack discoloration is a common issue that arises when water comes up through the pavement where cracks or pavement failure is occurring. As the days get warmer, the sun heats up the pavement and draws the moisture back to the surface.

If you sealcoat a parking lot and notice that the cracks, alligatored areas or low spots in the pavement have a discoloration of the sealer, typically brown, that is due to the sealer re-emulsifying. In other words, the sealer reabsorbs the water

Sealer cannot form a film if there is constant water present. The use of additives can help reduce some staining, but remember this is not a sealer problem, this is a water problem.

![]() What causes cracks in Asphalt Pavement?

What causes cracks in Asphalt Pavement?

![]()

Cracking is most often the fault of one of these three common culprits:

- Moisture – powerful and persistent, water begins to break down a paved driveway almost immediately.

- Sun – another powerful force of nature, the sun beats down on asphalt, creating heat and breaks down the substances contained in this aggregate material. Sunshine dries up the surface, and although too much moisture causes asphalt to wear down and crack, not enough moisture creates similar results.

- Ground Movements – the ground constantly shifts due to seasonal conditions such as frost and thaw. Asphalt driveways are installed on a bed of gravel spread across grades earth. When the earth moves, the gravel naturally movies and puts force on the asphalt, often resulting in cracks and/or potholes.